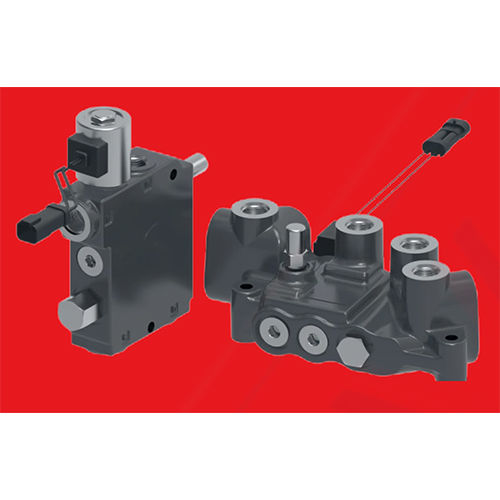

Subsystem Valves

उत्पाद विवरण:

- वाल्व का प्रकार Subsystem Isolation / Directional Control Valve

- विशेषताएँ High Flow Rate, Leak-Proof Construction, Quick Response

- वाल्व का आकार Varies by Application (Standard and Custom Sizes)

- कंट्रोल सिस्टम Manual, Electric, or Pneumatic Control

- कनेक्शन का प्रकार Threaded, Flanged, or Quick Connect

- मटेरियल Stainless Steel / Brass / Aluminum

- वोल्टेज 24V DC / 110V AC / 220V AC

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Subsystem Isolation / Directional Control Valve

- High Flow Rate, Leak-Proof Construction, Quick Response

- Solenoid Operated, Direct Acting

- Varies by Application (Standard and Custom Sizes)

- 1/8 to 1 BSP/NPT

- 24V DC / 110V AC / 220V AC

- -20°C to +80°C

- Stainless Steel / Brass / Aluminum

- Corrosion-resistant Stainless

- Hydraulic and Pneumatic Systems

- Threaded, Flanged, or Quick Connect

- Multiple Pin Configurations Available

- Manual, Electric, or Pneumatic Control

- PTFE / NBR / EPDM

उत्पाद वर्णन

- Unlike configurable valves, which can serve multiple purposes in a machine, a subsystem valve is designed for a specific use within a complex system.

- Our line of subsystem valves includes brake valves and self-leveling valves.

Versatile Mounting and Superior Design

These subsystem valves allow universal mounting in any position, catering to varied installation needs across industrial settings. The modular, compact design supports space-saving layouts, while prefabricated mounting holes ensure a simple and swift installation process. Each valve is engineered for both standard threaded and customizable quick-connect options, adapting readily to application requirements and maximizing system adaptability.

Reliable Performance and Extended Durability

With a response time under 20 milliseconds, over one million cycle durability, and PTFE/NBR/EPDM sealing, these valves provide swift and stable control in critical operations. Corrosion-resistant materials and surface finishes like electropolishing or powder coating guarantee long service life. Leak-proof, bubble-tight construction reduces maintenance demands, ensuring consistent performance for fluid control in India's demanding industrial environments.

Advanced Control and Safety Features

Subsystem Valves come with manual, electric, or pneumatic controls for operational flexibility. They support auxiliary porting for optional position feedback and are equipped with high IP-rated coil protection against dust and water ingress. The valves are approved under CE and ISO 9001 standards, providing confidence in quality and regulatory compliance for industry use.

FAQ's of Subsystem Valves:

Q: How can these subsystem valves be mounted in my application?

A: These valves support universal mounting, allowing them to be installed in any orientation. Prefabricated mounting holes simplify installation and are adaptable for various system configurations.Q: What benefits does the modular and compact design offer?

A: The compact, modular construction enables efficient use of space, ease of expansion, and rapid maintenance or replacement, making it ideal for streamlined hydraulic or pneumatic subsystems.Q: When is it appropriate to use these valves in hydraulic or pneumatic systems?

A: These subsystem valves are suitable whenever precise isolation or directional control is needed, especially in systems requiring fast response times, high durability, and leak-proof performance.Q: Where can I utilize these valves given their certifications and features?

A: Certified with CE and ISO 9001, these valves can be safely used across a range of industries, including manufacturing, processing, and automation, throughout India and internationally.Q: What is the process for customizing end connections and auxiliary porting?

A: You can specify your preferred connection type (threaded, flanged, or quick-connect) and request auxiliary ports for position feedback during ordering. Our team will configure the valve to match your application needs.Q: How does the zero internal leakage benefit my operation?

A: Zero internal (bubble-tight) leakage ensures no media escapes within the valve, enhancing efficiency, safety, and reducing maintenance costs while protecting downstream components.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें