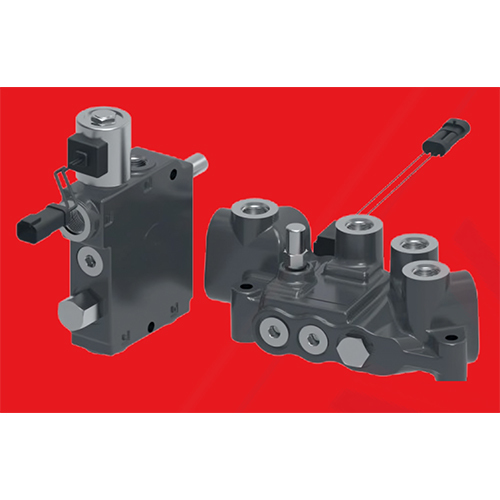

Standard German BH Flange Group 1

उत्पाद विवरण:

- विशेषताएँ Corrosion resistance, easy installation, DIN-EN standard

- कंट्रोल सिस्टम Manual or automated control integration supported

- वाल्व का प्रकार Flange for disc or butterfly valve

- कनेक्शन का प्रकार Flanged with bolt-hole pattern according to DIN

- मटेरियल Cast iron, carbon steel, or stainless steel

- वाल्व का आकार 1/2 inch to 2 inches

- वोल्टेज N/A (mechanical component)

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Flange for disc or butterfly valve

- DIN standard, customized as required

- Standard German BH Flange Group 1

- Corrosion resistance, easy installation, DIN-EN standard

- Manual or automated control integration supported

- Steel or stainless steel

- N/A (mechanical component)

- DN10 to DN50

- 1/2 inch to 2 inches

- NBR or FKM gasket compatible

- Flanged with bolt-hole pattern according to DIN

- -20°C to +120°C

- Cast iron, carbon steel, or stainless steel

- Industrial pipe fitting, hydraulic and pneumatic applications

उत्पाद वर्णन

Technical Details :

- Displacements from 0.91 cm3/rev to9.88 cm3/rev

- Maximum pressures upto 300 bar

- Rotation speeds upto 6000 rpm

Options Available:

- Viton

- Maximum pressure valve

- Anti-cavitation valve

- Inlet and outlet in the body,front flange or back cover

- Available shafts: Milled shaft, Splined shaft

Robust Construction for Industrial Applications

The BH Flange Group 1 is manufactured with durability in mind, utilizing high-grade materials such as cast iron, carbon steel, or stainless steel. Its corrosion-resistant finish and adherence to DIN-EN standards make it ideal for demanding environments. With a round structure, raised face, and precision bolt holes, this flange ensures a reliable and leak-free connection in industrial piping systems, hydraulic lines, and pneumatic applications.

Versatile Integration and Easy Maintenance

Designed to support both manual and automated control systems, these flanges are easy to install and require minimal maintenance. Compatibility with standard industrial gaskets and multiple valve types-including disc and butterfly valves-enhances versatility. The anti-corrosive coated or painted surface finish further reduces upkeep, making it a low-maintenance choice for ongoing industrial use.

FAQ's of Standard German BH Flange Group 1:

Q: How is the Standard German BH Flange Group 1 installed in a piping system?

A: The BH Flange Group 1 is mounted to pipes using a bolt-hole pattern that aligns with DIN 2501/EN 1092-1 specifications. Simply position the flange, insert the appropriate bolts (4 or 8, based on size), and tighten to secure a leak-proof connection using a compatible standard gasket.Q: What applications are suitable for the BH Flange Group 1?

A: This flange is ideal for industrial pipe fittings, hydraulic and pneumatic systems, as well as installations handling water, oil, air, and various gases. Its robust build and sealing options make it versatile for a wide range of industrial settings.Q: When should I use a raised face flange type?

A: A raised face design is recommended when you require effectively sealed connections capable of handling higher pressures (up to 16 bar) and temperature variations from -20C to +120C, providing extra sealing capability with standard industrial gaskets.Q: Where can I find BH Flange Group 1 distributors or suppliers in India?

A: Numerous industrial distributors and suppliers across India offer BH Flange Group 1 flanges that comply with DIN 2501/EN 1092-1. Look for suppliers specifying DIN-EN standards to ensure compatibility.Q: What is the process for integrating these flanges into automated or manual control systems?

A: The flanges can be paired with either manual valves or actuators, providing flexibility for both manual and automated control integration. Their standardized connection and pin structure make coupling with various control systems straightforward.Q: How does the anti-corrosive coating benefit long-term usage?

A: The anti-corrosive coating or paint protects the flange from rust and chemical exposure, extending its operational life and reducing the need for frequent maintenance, especially in harsh environments.Q: What makes the BH Flange Group 1 easy to maintain?

A: With its corrosion-resistant surface and straightforward installation process, the flange requires minimal maintenance. Periodic checks for seal integrity and surface condition suffice for most industrial applications.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें