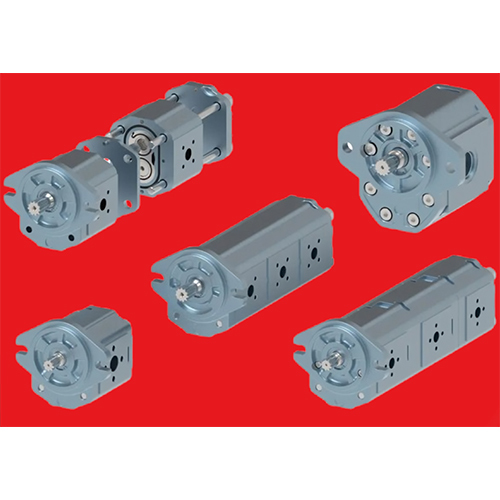

Gearme Aluminium Gear Pumps

उत्पाद विवरण:

- इनलेट/आउटलेट 1/2 / 3/4 BSP

- काम करने का तापमान -40°C to +80°C

- माउंटिंग टाइप Flange / Foot

- वोल्टेज 12V / 24V

- कंट्रोल सिस्टम Manual/Automatic

- स्पीड 1450-3000 RPM

- डिस्चार्ज प्रेशर Up to 8 Bar

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Positive displacement

- Up to 30 m

- Up to 8 Bar

- Aluminium

- 1450-3000 RPM

- Manual/Automatic

- 12V / 24V

- Up to 210 LPH

- Flange / Foot

- -40°C to +80°C

- IS/ISO Certified

- 1/2 / 3/4 BSP

- 5 metres

- Self-priming

- 12-35 LPM

- Standard

- Corrosion resistant, compact design, lightweight

- Viton / Nitrile

- 50/60 Hz

- Low noise (<70 dB)

उत्पाद वर्णन

- Our GearMe pumps are pressure balanced for exceptional efficiency and feature high-strength extruded-aluminum bodies and aluminum covers and flanges.

- Available with displacements from 1.18 cm3 to 88.2 cm3 [0.07 in3 to 5.38 in3], the high-performance pumps from this reliable series are ideal for a wide range of applications.

Reliable Performance for Demanding Applications

Gearme Aluminium Gear Pumps are built to meet the rigorous requirements of industrial and mobile equipment. Their high-pressure capacity (up to 8 Bar), self-priming suction, and continuous duty operation ensure consistent fluid transfer in environments such as hydraulic systems, fluid discharge, and transfer processes.

Advanced Engineering for Longevity

Equipped with splash lubrication and double lip seals, these gear pumps minimize wear and leakage. Anodized aluminium housings further amplify corrosion resistance, guaranteeing long-lasting service even under challenging conditions. The low-maintenance design means fewer interruptions and cost-effective operation.

Flexible Installation and Operation

Available in flange and foot mounting configurations, Gearme pumps suit a variety of setup requirements. Users can opt for manual or automatic control systems, adjusting to different process demands. With lightweight construction and compact design, these pumps are easy to handle and integrate into new or existing systems.

FAQ's of Gearme Aluminium Gear Pumps:

Q: How does the Gearme Aluminium Gear Pump achieve self-priming capability?

A: The pump employs positive displacement rotary gear technology, enabling it to create sufficient vacuum at the inlet to draw fluids without the need for manual priming, making it ideal for both stationary and mobile applications.Q: What fluids can the Gearme gear pump transfer efficiently?

A: This pump is engineered to handle hydraulic oil and a wide range of industrial fluids with viscosities up to 1000 cSt. Its corrosion-resistant construction and double lip seal facilitate safe and efficient transfer of these materials.Q: When is it necessary to replace seals or other parts in the pump?

A: Replacement is recommended if you observe leakage, reduced flow rate, or increased noise levels. The double lip seal design and availability of genuine replacement parts ensure maintenance is straightforward and infrequent.Q: Where can the Gearme Aluminium Gear Pump be installed?

A: These pumps can be mounted using either flange or foot mounting, providing flexibility for installation in industrial machinery, mobile equipment, or site-based transfer stations across various environments.Q: What maintenance procedures are required for these gear pumps?

A: Due to their low-maintenance design, basic upkeep involves periodic inspection of seals and lubricants. The splash lubrication system and durable components reduce the need for frequent servicing.Q: How does the pump's anodized surface finish benefit users?

A: Anodization enhances the aluminium's resistance to corrosion and abrasion, prolonging the pump's lifespan even in harsh industrial settings and reducing the chance of premature wear.Q: What advantages do the direct coupling and electric motor drive types offer?

A: Direct coupling ensures efficient power transmission with minimal loss, while the electric motor option allows for consistent performance. Users can choose the drive that suits their operational setup and required voltage (12V/24V).Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें