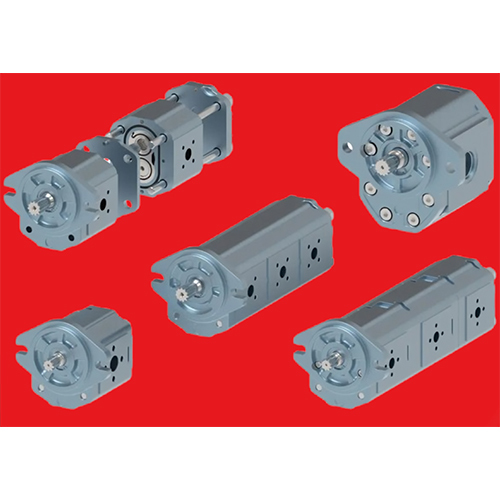

Cast Iron Gear Pumps

उत्पाद विवरण:

- माउंटिंग टाइप Foot / Base Mounted

- मैक्स सक्शन 5 meters

- सिर का आकार Up to 80 meters

- वोल्टेज 220V / 415V

- कंट्रोल सिस्टम Manual / Automated

- थ्योरी

- फ़्रिक्वेंसी 50 Hz / 60 Hz

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Cast Iron

- 10 LPM to 500 LPM

- Low

- 1/2 to 3 BSP (Customizable)

- 50 Hz / 60 Hz

- Standard

- Up to 10 bar

- Up to 1440 RPM

- 0.5 m3/hr to 30 m3/hr

- -10°C to +80°C

- Compact Design, Easy Maintenance, Durable Construction

- Positive Displacement

- Foot / Base Mounted

- ISI / ISO Certified

- 5 meters

- Up to 80 meters

- Self-priming

- Manual / Automated

- Mechanical Seal / Gland Packing

- 220V / 415V

उत्पाद वर्णन

- Our long-lasting Rugid cast-iron gear pumps are made for high-flow applications that demand peak performance under extreme conditions including pressures up to 276 bar [4,000 psi] and intermittent temperatures up to 115 deg C [239 deg F].

- They feature displacements up to 90 cm3 [5.40 in3], durable cast-iron construction, and an advanced pressure plate design.

Versatile Performance for Demanding Applications

Designed to handle a range of fluids, including oils and viscous liquids, the Cast Iron Gear Pump excels in hydraulic systems, industrial lube transfer, and oil circulation. Its self-priming, positive displacement gear design ensures high efficiency and consistent performance, even with fluctuating fluid viscosities or challenging operating environments.

Durable Construction and Easy Maintenance

Constructed from robust cast iron and equipped with anti-corrosive paint, this pump withstands harsh conditions. The choice of EN8 or SS410 shaft material and advanced sealing options (mechanical seal/gland packing) minimize leakage and downtime. The compact profile and foot-mounted design ensure straightforward installation and maintenance.

Flexible Configurations and Control Options

Offering direct or V-belt drive compatibility and manual or automated control systems, the pump adapts seamlessly to diverse site requirements. With multiple voltage choices and inlet/outlet options, it integrates easily into existing industrial setups, ensuring reliable operation across various capacities and pressures.

FAQs of Cast Iron Gear Pumps:

Q: How can I determine if this gear pump is suitable for my industrial fluid transfer application?

A: To select the right pump, match your required flow rate, pressure, fluid viscosity, and installation environment with the pumps specificationssuch as flow rates up to 500 LPM, viscosities up to 100,000 cSt, and a working temperature range from -10C to +80C. The pumps versatility makes it ideal for oil, hydraulic, and viscous liquid transfer.Q: What maintenance procedures are recommended for the Cast Iron Gear Pump?

A: Routine inspection of seals, shaft, and lubrication is advised, even though the pump is self-lubricated by the pumped fluid. Depending on usage, check for unusual noise, vibration, or drop in performance, and periodically verify that anti-corrosive coatings and mounting bolts remain intact.Q: When should I use mechanical seal versus gland packing for sealing?

A: Mechanical seals are preferred for leak-sensitive, high-precision, or automated operations, as they offer better sealing and lower maintenance. Gland packing may be selected for simpler, manually monitored systems or when cost-effectiveness and ease of replacement are priorities.Q: Where can the Cast Iron Gear Pump be installed?

A: Thanks to its compact, foot-mounted design and compatibility with both direct and V-belt drives, this pump can be installed in a wide array of locations, including factories, machine shops, oil transfer stations, or integrated into hydraulic and lube oil systemsacross industrial environments in India.Q: What is the process for customizing inlet/outlet connections or other features?

A: You can request customized port connections, from 1/2 to 3 BSP (threaded or flanged), during order placement. Further customizations like shaft material, control system (manual or automated), and drive type can be accommodated based on your specific project requirements.Q: How does this pump benefit operators and industrial processes?

A: Operators benefit from its self-priming capability, low noise levels, and consistent positive displacement for efficient, reliable fluid transfer. The durable, anti-corrosive build reduces downtime and maintenance, ensuring long-term operational savings.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें