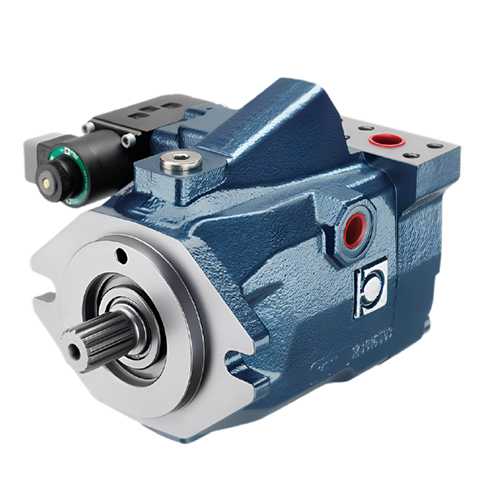

Reverse Displacement Axial Piston Motors

Product Details:

- Efficacy Over 90%

- Ambient Temperature -20C to +80C

- Noise Level Below 68 dB

- Cooling Method External Oil Cooling

- Pressure Up to 450 bar

- Standard ISO 9001:2015

- Features Reverse Displacement, Axial Piston design, High Efficiency, Compact Structure, Overload Protection, Quiet Operation

- Click to View more

X

Reverse Displacement Axial Piston Motors Product Specifications

- Depends on Model (Typical: 380mm x 220mm x 220mm)

- Hydraulic

- Up to 125 HP

- Overload Protection

- Up to 100 kW

- Up to 680 Nm

- 48 kg (Approximate)

- Three Phase

- 100 kW

- Reverse Displacement, Axial Piston design, High Efficiency, Compact Structure, Overload Protection, Quiet Operation

- Up to 450 bar

- ISO 9001:2015

- Below 68 dB

- Variable up to 4000 RPM

- External Oil Cooling

- -20C to +80C

- Over 90%

- Axial Piston Hydraulic Motor

- Blue/Grey

- IP65

- Hydraulic Start

- Reverse Displacement Axial Piston Motor

- Fully Sealed

- 32 mm

- Flange Mount

- Heavy-Duty Roller Bearing

- Hydraulic

Product Description

Reversing the airflow in cooling and cleaning systems often involves complex valving and leak points, but with our reverse displacement motors (RDMs), you can avoid these problems while boosting machine effciency and reducing system costs and service downtime.

Advanced Variable Displacement Technology

Our motors employ state-of-the-art axial piston design with reverse displacement capability, allowing variable displacement from 71 to 160 cc/rev. This technology supports precise flow control and maximizes energy efficiency, making these motors ideal for applications requiring responsive power delivery and direction reversal in demanding environments.

Built for Rugged Performance and Longevity

Crafted from high-strength alloy steel and protected by heavy-duty seals, the motors ensure over 20,000 hours of reliable operation. The compact structure, robust roller bearings, and external oil cooling system collectively minimize wear and maintain performance under continuous heavy loads, even when operating at pressures up to 450 bar.

Versatility Across Multiple Industries

With IE3-equivalent efficiency, bi-directional capabilities, and standard BSP/SAE port threads, these motors integrate seamlessly in industrial plants, mobile equipment, agricultural machinery, and construction projects. Their flange mounting and compact footprint (typ. 380x220x220 mm) simplify installation, while overload protection enhances safety in diverse settings.

FAQ's of Reverse Displacement Axial Piston Motors:

Q: How does the reverse displacement function benefit applications using these axial piston motors?

A: The reverse displacement feature allows the motor to rapidly change rotational direction and control output flow, making it ideal for machinery that requires quick and precise reversing operations, such as construction or industrial equipment.Q: What process should be followed for installing these motors in mobile machinery?

A: Installation involves securing the flange mount to the designated frame, ensuring compatibility with the standard BSP/SAE port threads. Connect hydraulic lines with ISO VG 46/68 oil and complete electrical integration if necessary, before initiating hydraulic start for testing.Q: When and where are these motors most beneficial for industrial users?

A: These motors are most beneficial in environments that demand high efficiency, variable speed, and enduring performance under heavy loads - such as manufacturing plants, agricultural equipment, and heavy-duty mobile or construction machinery.Q: What type of maintenance is required to ensure the service life exceeds 20,000 operating hours?

A: Routine maintenance includes regular oil changes with recommended hydraulic fluids, inspection of NRB seals, monitoring external oil cooling efficiency, and checking for abnormal noise levels to prevent wear on the roller bearings.Q: How can users optimize the efficiency and output power of the motor during operation?

A: To maximize efficiency (over 90%) and output power (up to 100 kW), maintain optimal hydraulic oil quality and temperature, ensure external oil cooling is functional, and operate the motor within the recommended speed and pressure ranges.Q: Why is the use of high-strength alloy steel important in the motor's construction?

A: High-strength alloy steel increases durability and resistance to fatigue, allowing the motor to withstand demanding applications, high pressures (up to 450 bar), and extended operational cycles without compromising performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free