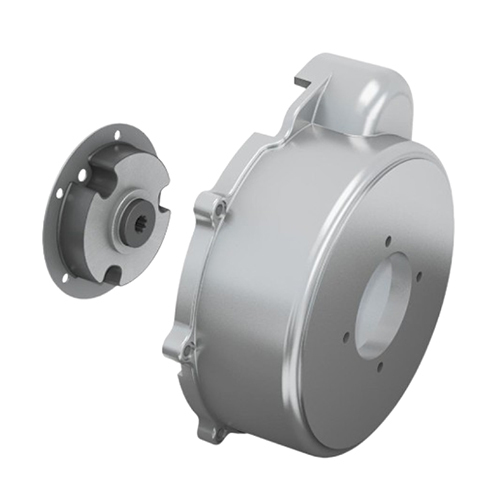

Rigid Coupling System

उत्पाद विवरण:

- सीलिंग EPDM or NBR rubber gasket

- कनेक्शन

- टॉर्क Rated up to 400 Nm or as specified for model

- ऊबा देना Standard through bore, customizable as required

- मैक्स। स्पीड Up to 3600 RPM for suitable models

- हेड कोड

- मटेरियल

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Range from 1 inch to 12 inches

- EPDM or NBR rubber gasket

- ANSI/AWWA C606-15 or equivalent

- Rated up to 400 Nm or as specified for model

- Depending on pipe specification matched

- Standard through bore, customizable as required

- Up to 3600 RPM for suitable models

- Pipe and tube joining in industrial, water supply, and fire protection pipelines

उत्पाद वर्णन

Discover the fresh, new release thats in high demand among top-ranking industrial solutions: our Crowning Rigid Coupling System. Designed for enviable performance in extreme environments, this system boasts high corrosion resistance, a versatile -40C to +120C temperature range, and easy slip-on installation. Choose from black oxide or zinc-plated finishes for robust durability. Not suitable for misalignment but engineered for seamless, secure pipe and tube connections, this ANSI/AWWA C606-15-compliant system fits a range of diameters and offers custom sizing for every need.

Rigid Coupling System: Competitive Edge and Applications

Our Rigid Coupling System stands out as a top-ranking solution with crowning advantages such as high corrosion resistance, quick installation, and low maintenance needs. With a strong, dependable design, it is in demand for industrial, water supply, and fire protection pipeline connections. The enviable versatility extends to custom sizes and finishes, ensuring a perfect fit. Commercial users benefit from robust performance and dependable sealing, making it ideal for a variety of challenging operational environments.

Certifications, Markets, and Flexible Transactions

The Rigid Coupling System carries recognized certifications including ANSI/AWWA C606-15 compliance, crowning it among trusted products. Serving primarily the Indian market, we offer detailed quotations and support for transport services to ensure timely delivery. Flexible payment terms are available to support suppliers, distributors, and end-users. Our packaging optionsindividual or bulkfurther guarantee secure arrival, while our customer service covers the entire process from quotation to installation.

Rigid Coupling System: Competitive Edge and Applications

Our Rigid Coupling System stands out as a top-ranking solution with crowning advantages such as high corrosion resistance, quick installation, and low maintenance needs. With a strong, dependable design, it is in demand for industrial, water supply, and fire protection pipeline connections. The enviable versatility extends to custom sizes and finishes, ensuring a perfect fit. Commercial users benefit from robust performance and dependable sealing, making it ideal for a variety of challenging operational environments.

Certifications, Markets, and Flexible Transactions

The Rigid Coupling System carries recognized certifications including ANSI/AWWA C606-15 compliance, crowning it among trusted products. Serving primarily the Indian market, we offer detailed quotations and support for transport services to ensure timely delivery. Flexible payment terms are available to support suppliers, distributors, and end-users. Our packaging optionsindividual or bulkfurther guarantee secure arrival, while our customer service covers the entire process from quotation to installation.

FAQs of Rigid Coupling System:

Q: How easy is it to install the Rigid Coupling System?

A: The Rigid Coupling System features an easy, slip-on installation process requiring only set screws or clamp bolts, making it straightforward for quick assembly and minimal downtime.Q: What are the primary benefits of using this coupling in industrial pipelines?

A: This coupling offers high corrosion resistance, superior sealing with EPDM or NBR rubber gaskets, and supports high-speed operation up to 3600 RPM, making it ideal for demanding industrial applications.Q: When should I consider periodic maintenance for the coupling?

A: Periodic checks are recommended to ensure optimal performance. While maintenance requirements are low, a visual inspection during routine system checks helps detect wear or potential loosening of fasteners.Q: Where can I request a quotation or custom sizes for specific applications?

A: Quotations and requests for custom sizes can be made directly with our sales department or authorized distributors in India for tailored solutions and volume pricing.Q: What processes and surface treatments are available for these couplings?

A: Depending on your requirements, the couplings can be provided galvanized, painted, or electroplated, offering enviable durability and compatibility with a range of environmental conditions.Q: How does the rigid coupling system handle corrosion?

A: With black oxide or zinc-plated finishes and high-quality ductile iron or carbon steel construction, the system provides exceptional corrosion resistance, ensuring long-term operation in harsh or wet environments.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें