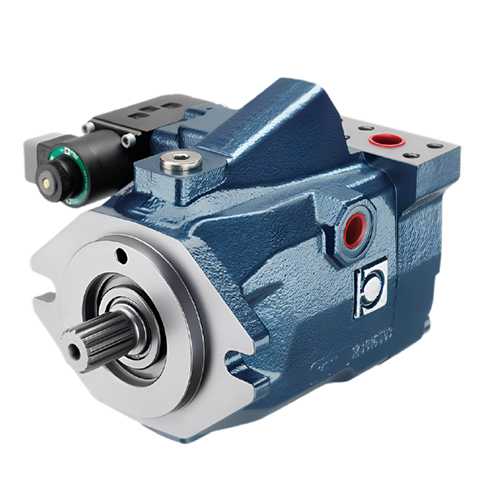

Piston Motors

उत्पाद विवरण:

- टॉर्क High Torque Output

- प्रभावोत्पादकता IE2 High Efficiency

- हॉर्स पावर Up to 250 HP

- मुहरबंद प्रकार

- ठंडा करने की विधि Air/Water Cooled

- मोटर का प्रकार Axial Piston Motor

- मौजूदा क़िस्म AC

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Customizable

- Up to 250 HP

- Flange/Foot Mounted

- -20°C to +45°C

- Robust Construction, Long Service Life, High Efficiency

- 220/380 V

- 50/60 Hz

- Low Noise Operation

- Varies by Model (Approx. 50 to 200 kg)

- As per Model (Standard Sizes)

- Direct On-Line (DOL)

- Heavy Duty Ball Bearing

- 50/60 Hz

- 220-415 V

- Silver/Grey

- Up to 250 kW

- AC

- Axial Piston Motor

- Air/Water Cooled

- Up to 250 HP

- Up to 3000 RPM

- IE2 High Efficiency

- High Torque Output

- Depends on Model

उत्पाद वर्णन

- With displacements from 25 cm3 to 250 cm3 [1.5 in3 to 15.3 in3], our axial piston motors are suitable for both open- and closed-circuit systems.

- Controls for fixed, two-position, and continuously variable displacement are available, as is the zero-degree option.

उत्पाद विवरण :

Usage/Application : Industrial

Power Source : Electric

Material : Mild Steel

Voltage : 240 V

Circuit Type : Closed

Country of Origin : Made in India.

Color : Black

Superior Performance for Demanding Applications

Designed for Indias rigorous industrial and construction sectors, our piston motors provide high torque and powerful performance at pressures up to 350 bar. Their premium build guarantees robust and reliable function in high-load scenarios, ensuring equipment runs smoothly under varied conditions. Customizable power ratings and mounting options meet a broad range of application needs.

Long Service Life and Low Maintenance

Precision engineering with high-quality alloy steel or cast iron housings and mechanical seals extends these motors operational lifespan. Heavy-duty ball bearings and efficient cooling systems support continuous operation with minimal downtime, reducing maintenance efforts and costs common in intensive environments.

Flexible Design and Easy Integration

Available in flange or foot-mounted designs and fitted with standard SAE or customized connection ports, these motors integrate effortlessly into new or existing hydraulic systems. Adaptable to various voltage and frequency requirements, installations are streamlined, meeting differing application demands with ease.

FAQs of Piston Motors:

Q: How do I choose the right piston motor displacement for my application?

A: Select the displacement (101000 cc/rev) based on the desired flow rate and hydraulic systems operating pressure. For high torque, low speed tasks, choose a larger displacement; for high speed, lower torque, select a smaller displacement. Consult our distributor in India for personalized guidance.Q: What makes these piston motors suitable for industrial and construction machinery?

A: With high output power (up to 250 kW), robust alloy steel or cast iron casings, overload protection, and high efficiency (IE2), these motors withstand rigorous industrial and construction environments, handling heavy-duty cycles, variable voltages, and demanding loads.Q: When is bi-directional rotation advantageous for my operations?

A: Bi-directional rotation is ideal when machinery requires reversible motion, such as in mobile equipment or specific construction tasks. It increases operational flexibility, allowing direction changes without reconfiguring the motor setup.Q: Where can these piston motors be installed, and what are the mounting options?

A: These motors are designed for flexible installation in industrial facilities, mobile equipment, and on-site construction machinery. Standard flange or foot mounting options and customizable shaft diameters simplify integration into existing systems.Q: What is the standard maintenance process for these motors?

A: Routine checks include monitoring hydraulic oil quality, inspecting seals, and verifying bearing condition. Due to their heavy-duty ball bearings and robust mechanical seals, these motors require less frequent maintenance than comparable models, reducing overall service intervals.Q: How does the overload protection feature benefit operation?

A: Overload protection helps safeguard the motor and connected equipment from damage under excessive load, minimizing downtime and maintenance costs, while ensuring operational safety and longevity.Q: What are the key benefits of the air/water cooling options?

A: Air and water cooling methods enhance temperature control, supporting continuous operation even in challenging environments. This reduces thermal stress on the motor, prolonging service life and preventing overheating during intensive use.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email