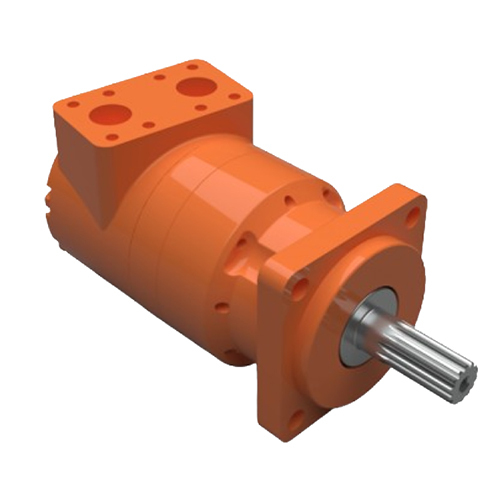

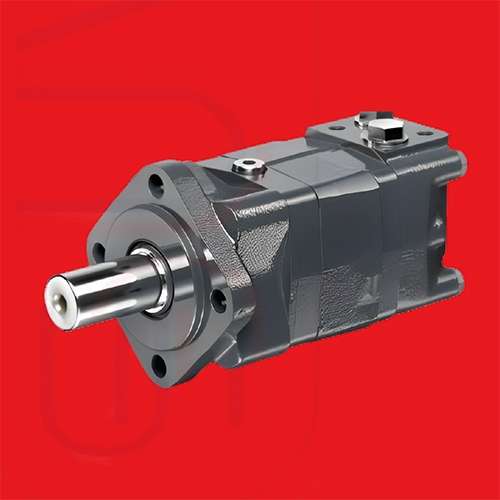

Orbital Motor OML

Product Details:

- Sealed Type Sealed Construction

- Current Type Hydraulic

- Starting Type Direct Start

- Torque Up to 392 Nm

- Noise Level Less than 75 dB(A)

- Pressure Max 140 bar

- Motor Type Orbital Hydraulic Motor

- Click to View more

X

Orbital Motor OML Product Specifications

- Hydraulic Motor (no electrical phase)

- 5.5 kg

- Hydraulic Driven

- Up to 8 kW

- Direct Start

- Sealed Construction

- Hydraulic

- Less than 75 dB(A)

- Up to 392 Nm

- Approx. 180x110x110 mm

- -20C to +80C

- Up to 10.5 HP

- Orbital Hydraulic Motor

- 25 mm

- Max 140 bar

- Flange Mounted

- High Starting Torque, Compact Design, Smooth Operation

- Varies by Model

- Overload Protection

- Orbital Motor

- Blue/Grey

- Hydraulic Fluid Circulation

- up to 1950 rpm

- Roller Bearing

- OEM Standard

- High Efficiency

- IP54

Product Description

The Orbital Motor OML is a redoubtable solution blending superb efficiency with noble reliability. Tailored for the cost-effective procurement needs of agricultural, industrial, and construction sectors, it offers a special rate advantage for bulk orders or ongoing supply. With displacement options from 50-400 cc/rev, bi-directional rotation, keyed/splined shafts, and corrosion resistance, this compact hydraulic motor provides consistent, high-performance output up to 8 kW (10.5 HP) and torque to 392 Nm. Sealed construction, IP54 rating, and smooth, direct-start operation ensure longevity and seamless utility where superior standards are indispensable.

Orbital Motor OML: Usage Directions and Application Range

Use the Orbital Motor OML by mounting it with its flange setup and connecting to your hydraulic system using the 1/2" BSP port. This device is widely used in agricultural equipment, industrial machines, and construction vehicles for driving, lifting, or moving parts requiring reliable power. Its bidirectional rotation and robust overload protection make it ideal for applications demanding frequent directional changes, smooth start-ups, and exceptional durability under varying load conditions.

Export Markets, FOB Port, and Certifications of Orbital Motor OML

The Orbital Motor OML enjoys prominent market value in export markets including South Asia, Middle East, and Africa. Each motor is dispatched from recognized FOB ports in India, ensuring prompt shipping and reliable packaging to international standards. Certifications including OEM compliance guarantee quality and performance. Its reputation as a preferred supplier choice is amplified by trust in our packaging efficiency, shipment reliability, and the consistent excellence reflected in our exported products.

Orbital Motor OML: Usage Directions and Application Range

Use the Orbital Motor OML by mounting it with its flange setup and connecting to your hydraulic system using the 1/2" BSP port. This device is widely used in agricultural equipment, industrial machines, and construction vehicles for driving, lifting, or moving parts requiring reliable power. Its bidirectional rotation and robust overload protection make it ideal for applications demanding frequent directional changes, smooth start-ups, and exceptional durability under varying load conditions.

Export Markets, FOB Port, and Certifications of Orbital Motor OML

The Orbital Motor OML enjoys prominent market value in export markets including South Asia, Middle East, and Africa. Each motor is dispatched from recognized FOB ports in India, ensuring prompt shipping and reliable packaging to international standards. Certifications including OEM compliance guarantee quality and performance. Its reputation as a preferred supplier choice is amplified by trust in our packaging efficiency, shipment reliability, and the consistent excellence reflected in our exported products.

FAQ's of Orbital Motor OML:

Q: How is the Orbital Motor OML typically installed and started?

A: It is flange-mounted onto compatible machinery, connected via a 1/2" BSP hydraulic port, and supports direct-start operation. Ensure all safety and operational standards are met before activation.Q: What are the main benefits of using this orbital motor in industrial and agricultural applications?

A: The main benefits include cost-effectiveness, high starting torque, smooth and bi-directional operation, reliable seal materials, and excellent corrosion resistance, making it suitable for demanding environments.Q: In which sectors is the Orbital Motor OML most commonly used?

A: It is widely used in agricultural, industrial, and construction machinery-such as conveyors, harvesters, loaders, and other hydraulic-driven equipment requiring compact power sources.Q: What is the process for procuring the Orbital Motor OML at a special rate?

A: To procure at a special rate, contact our sales team or authorized distributors in India, specifying volume requirements or ongoing supply needs for potential discounts.Q: Where can I find authorized suppliers or distributors of the Orbital Motor OML?

A: Authorized suppliers and distributors can be located through our website or by contacting our sales office directly for verified contact points across India and export markets.Q: What are the key features that ensure the durability of the Orbital Motor OML?

A: The motor features sealed construction, corrosion resistance, IP54-rated enclosure, NBR/FKM seals, and robust overload protection, all contributing to long service life in harsh conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free